|

Shanghai Heng Sheng Industry Co., Ltd

|

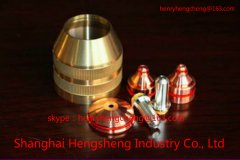

Plasma Cutting Machine Nozzle .11.848.311.618 G2518 For Kjellberg Plasma Machine

| Payment Terms: | T/T,WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

In recent years, we have been sold in lots of countries and regions in Europe and Asia and gained good reputation widely with excellent quality

Plasma Cutting Machine Nozzle .11.848.311.618 G2518 For Kjellberg Plasma Machine

In recent years, we have been sold in lots of countries and regions in Europe and Asia and gained good reputation widely with excellent quality . In order to meet customers' requirements and improve product quality, our company has already realized mechanical processing numerical control automatization production, and been committed to manufacturing products with best quality.

We are a professional manufacturer of plasma cutter consumables.

1. Can supply various models of plasma Consumables electrode, nozzle, shield, swirl ring, inner cap, retaining cap, water tube, torch body, such as HT4400, HPR400XD, HPR260XD, HPR130XD, HPR260, HPR130, HSD130, HD3070, HD4070, HT2000, MAX200, POWERMAX1650, POWERMAX1250, POWERMAX65, POWERMAX85, POWERMAX45, POWERMAX30 and so on.

2. Can make as per customer's requirements. Almost Every Parts Have A Lot Of Stock.

3.The strict quality control. Our products processed are using CNC machines, we have fifteen sets of high-precision testing equipment and Eighty experienced skilled workers.

4. Welcome to contact us. You Can Send Us E-Mail, Skype, WhatSapp, Wechat or Call us.

5.Outer packing:standard export carton.

6.Have any questions, pls feel free to inform us.

Machine | HEC NO. | Thum NO. | Ref NO. | Description |

Hifocus 280i Hifocus 360i Hifocus 440i (Carbon Steel) | K94211 | G901Y | .11.848.201.142 | Cooling tube |

K94212 | G902Y | .11.852.201.142 | Cooling tube | |

K94241 | G931Y | .11.848.401.142 | Cooling tube | |

K0402 | G002Y | .11.848.221.300 | Cathode O2 | |

K0105 | G015Y | .11.848.231.350 | Cathode O2 | |

K0101 | G011Y | .11.848.231.320 | Cathode O2 | |

K0106 | G016Y | .11.848.231.360 | Cathode O2 | |

K0402 | G092Y | .11.848.401.310 | Cathode O2 | |

K7441 | G101 | .11.848.221.145 | Gas guide | |

K1466 | G2006 | .11.848.221.406 | Nozzle O2 25A | |

K1467 | G2007 | .11.848.221.407 | Nozzle O2 35A | |

K54124 | G3004 | .11.848.201.1604 | Nozzle cap | |

K641515 | G4015 | .11.848.201.1515 | Swirl gas cap | |

K641220 | G4020 | .11.848.201.1520 | Swirl gas cap | |

K44191 | G501 | .11.848.201.081 | Protective cap | |

K0403 | G003Y | .11.848.221.310 | Gathode -O2 | |

K7442 | G102 | .11.848.221.146 | Gas guide | |

K1466 | G2006Y | .11.848.221.406 | Nozzle O2 | |

K1467 | G2007Y | .11.848.221.407 | Nozzle O2 | |

K1468 | G2008Y | .11.848.221.408 | Nozzle O2 50A | |

K14610 | G2010Y | .11.848.221.410 | Nozzle O2 80A | |

K14612 | G2012Y | .11.848.221.412 | Nozzle O2 120A | |

K14614 | G2014Y | .11.848.221.414 | Nozzle O2 160A | |

K14616 | G2016Y | .11.848.221.416 | Nozzle O2 200A | |

K14826 | G2326Y | .11.848.221.426 | Nozzle | |

K14830 | G2330Y | .11.848.221.430 | Nozzle | |

K14831 | G2331Y | .11.848.221.431 | Nozzle | |

K11014 | G2514 | .11.848.311.614 | Nozzle | |

K11015 | G2515 | .11.848.311.615 | Nozzle | |

K11016 | G2516 | .11.848.311.616 | Nozzle | |

K11018 | G2518 | .11.848.311.618 | Nozzle | |

K11125 | G2725 | .11.848.411.625 | Nozzle | |

K11127 | G2727 | .11.848.411.627 | Nozzle | |

K11129 | G2729 | .11.848.411.629 | Nozzle | |

K541228 | G3028 | .11.848.201.1628 | Nozzle cap | |

K641522 | G4022 | .11.848.201.1522 | Swirl gas cap | |

K641525 | G4025 | .11.848.201.1525 | Swirl gas cap | |

K641530 | G4030 | .11.848.201.1530 | Swirl gas cap | |

K04242 | G032Y | .11.848.421.310 | Cathode O2 | |

K04244 | G034Y | .11.848.421.330 | Cathode O2 | |

K74251 | G121 | .11.848.421.145 | Gas guide | |

K14826 | G2326Y | .11.848.421.426 | Nozzle O2 280A | |

K14830 | G2330Y | .11.848.421.430 | Nozzle O2 360A | |

K14831 | G2331Y | .11.848.421.431 | Nozzle -O2-400A | |

K541409 | G3209 | .11.848.401.1609 | Nozzle cap | |

K541419 | G3219 | .11.848.401.1619 | Nozzle cap | |

K541429 | G3229 | .11.848.401.1629 | Nozzle cap | |

K641745 | G4345 | .11.848.401.1545 | Swirl gas cap | |

K641750 | G4350 | .11.848.401.1550 | Swirl gas cap | |

K641755 | G4355 | .11.848.401.1555 | Swirl gas cap | |

K44201 | G521 | .11.848.401.081 | Protective cap | |

K94211 | G901Y | .11.848.201.142 | Water Tube | |

K94212 | G902Y | .11.852.201.142 | Water Tube | |

K94241 | G931Y | .11.848.401.142 | Water Tube |

Technical Support:

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut by this process include steel, aluminum.

COOLING PLASMA CUTTING SYSTEM CONSUMABLES AND RELATED SYSTEMS AND METHODS

In some aspects, electrodes can include a front portion shaped to matingly engage a nozzle of the plasma cutting system, the front portion having a first end comprising a plasma arc emitter disposed therein; and a rear portion thermally connected to a second end of the front portion, the rear portion shaped to slidingly engage with a complementary swirl ring of the plasma cutting system and including: an annular mating feature extending radially The basic plasma cutting process involves creating an electrical channel of ionized gas i.e. plasma from the plasma cutter itself, through the work piece to be cut, thus forming a completed electric circuit back to the plasma cutter via a grounding clamp. This is accomplished by a compressed gas (oxygen, air, inert and others depending on material being cut) which is blown through a focused nozzle at high speed toward the work piece. An electrical arc is then formed within the gas, between an electrode near or integrated into the gas nozzle and the work piece itself. The electrical arc ionizes some of the gas, thereby creating an electrically conductive channel of plasma. As electricity from the cutter torch travels down this plasma it delivers sufficient heat to melt through the work piece. At the same time, much of the high velocity plasma and compressed gas blow the hot molten metal away, thereby separating i.e. cutting through the work piece.

.jpg)

.jpg)