|

Shanghai Heng Sheng Industry Co., Ltd

|

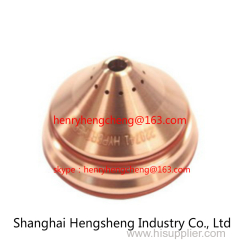

Plasma Cutter Electrode 220352 Hypertherm HPR130 Consumables For Hypertehrm Plasma Cutting Tips Long life Electrode

| Payment Terms: | T/T,WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hypertehrm Plasma Cutting Tips Long life Electrode

Plasma Cutting Electrode 220435 For Hypertehrm Plasma Torch Electrode

We are specialized in the production of plasma cutting machine torch consumables manufacturer, we are engaged in the industry for 9 years.

Our products are processed using CNC machines, we have fifteen sets of high-precision testing equipment and Eighty experienced skilled workers. Can make as per customer's requirements. Almost Every Parts Have A Lot Of Stock. The strict quality control. Our products processed are using CNC machines, we have fifteen sets of high-precision testing equipment and Eighty experienced skilled workers. Welcome to contact us. You Can Send Us E-Mail, Skype, WhatSapp, Wechat or Call us. Outer packing:standard export carton. Have any questions, pls feel free to inform us.

1. HEC Brand

We make metal cutting system and plasma cutter as well as torch and consumables. We make plasma cutting machine and fiber laser cutting machine with high quality and reliablity.

2. Cut Performance

HEC plasma consumables use high quality material and standard process to make sure the highest quality. Our consumables cutting performance is as the same as orginial OEM manufactory.

3. Good Price

HEC plasma consumables are good quality with low price make customers best requirement and saving money.

4. Big Catagory

HEC sell all kinds of plasma consumables include Hypertherm, EASB, Kjellberg, Koike and also supply some torch.

SERVICE

*Can make as per your samples or installation size.

*Provide OEM Service.

*Can pack as per your request.

Machine | HEC NO. | Ref NO. | Description |

HPR 130 HPR 260 HPR 130XD HPR 260XD HPR 400XD | H03192 | 220192 | Electrode,30Amp |

H03552 | 220552 | Electrode,50Amp | |

H03187 | 220187 | Electrode,80Amp | |

H03181 | 220181 | Electrode,130Amp | |

H03352 | 220352 | Electrode,200Amp | |

H03435 | 220435 | Electrode,260Amp | |

H03649 | 220649 | Electrode,130Amp Bevel | |

H03541 | 220541 | Electrode,260Amp Bevel | |

H03665 | 220665 | Electrode,130Amp(silver Plus) | |

H03666 | 220666 | Electrode,200Amp(silver Plus) | |

H03668 | 220668 | Electrode,260Amp(silver Plus) | |

H03629 | 220629 | Electrode,400Amp | |

H73180 | 220180 | Swirl Ring,30Amp | |

H73553 | 220553 | Swirl Ring,50Amp | |

H73353 | 220353 | Swirl Ring,200Amp | |

H73179 | 220179 | Swirl Ring,80/130/260Amp(Bevel) | |

H73436 | 220436 | Swirl Ring,260/260Amp(Bevel) | |

H73631 | 220631 | Swirl Ring,400/400Amp(Bevel) | |

H13193 | 220193 | Nozzle,30Amp | |

H13554 | 220554 | Nozzle,50Amp | |

H13188 | 220188 | Nozzle,80Amp | |

H13182 | 220182 | Nozzle,130Amp | |

H13354 | 220354 | Nozzle,200Amp | |

H13439 | 220439 | Nozzle,260Amp | |

H13646 | 220646 | Nozzle,130Amp(Bevel) | |

H13542 | 220542 | Nozzle,260Amp(Bevel) | |

H13632 | 220632 | Nozzle,400/400Amp(Bevel) | |

H33754 | 220754 | Retaining Cap 30/50Amp | |

H33176 | 220176 | Retaining Cap 80/130Amp | |

H33355 | 220355 | Retaining Cap 200Amp | |

H33433 | 220433 | Retaining Cap 260Amp | |

H33603 | 220603 | Retaining Cap (Bevel) 130/260Amp | |

H33756 | 220756 | Retaining Cap 80/130Amp | |

H33757 | 220757 | Retaining Cap 200Amp | |

H33760 | 220760 | Retaining Cap 260Amp | |

H33635 | 220635 | Retaining Cap 400/400Amp(Bevel) | |

H33740 | 220740 | Retaining Cap (Bevel) 130/260Amp | |

H23194 | 220194 | Shield,30Amp | |

H23555 | 220555 | Shield,50Amp | |

H23189 | 220189 | Shield,80Amp | |

H23183 | 220183 | Shield,130Amp | |

H23356 | 220356 | Shield,200Amp | |

H23440 | 220440 | Shield,260Amp | |

H23645 | 220645 | Shield,130Amp(Bevel) | |

H23545 | 220545 | Shield,260Amp(Bevel) | |

H23761 | 220761 | Shield,200Amp | |

H23764 | 220764 | Shield,260Amp | |

H23636 | 220636 | Shield,400/400Amp(Bevel) | |

H23742 | 220742 | Shield,130Amp(Bevel) | |

H23741 | 220741 | Shield,260Amp(Bevel) | |

H43173 | 220173 | Retaining Cap 30/50/80/130Amp | |

H43398 | 220398 | Retaining Cap 200/260/(Bevel)130/260Amp | |

H43747 | 220747 | Retaining Cap 30/50/80/130Amp | |

H43637 | 220637 | Retaining Cap 200/260/400Amp(Bevel) | |

H83818 | 128818 | HPR torch assembly | |

H83162 | 220162 | Quick-disconnect torch | |

H83163 | 220163 | Quick-disconnect recepticle | |

H83706 | 220706 | Quick-disconnect torch | |

H83705 | 220705 | Quick-disconnect recepticle | |

H93571 | 220571 | Water Tube with O-Ring | |

H93340 | 220340 | Water Tube with O-Ring(30/50/80/130/200/260Amp) | |

H93700 | 220700 | Bevel water tube(mild steel-130A) |

Technical Support:

Method for prolonging service life of consumable parts

1, keep the plasma gas dry and clean

Plasma system need to dry and clean gas plasma in order to work properly, dirty gas is usually compressed gas system, it will relationship exertion of life, resulting in non normal damage. Method for testing the quality of gas cutting torch in the test state, put a mirror in the below, torch gas consumption, if there is a gas and mist on the mirror, you need to identify the cause and correct.

2, cutting should start from the edge

As far as possible from the edge of the cut, and do not cut after the first punch. The use of the edge as the starting point will extend the life of the consumption, the right side

The method is that the nozzle is directly aligned with the edge of the workpiece and then starts the plasma arc.

3, to avoid the expansion of plasma arc

If the plasma is only extended to be exposed to the surface of the workpiece, this tension and expansion will occur at the beginning and end of the plasma arc, which will cause the nozzle to be damaged. If you use the right edge of the starting point, select the right "broken arc" signal time, this problem can be avoided.

4, to reduce unnecessary "starting arc (or arc)" time

When the arc starting nozzle and electrode consumption are very fast, before the start, should be put in the metal cutting torch within walking distance.

.jpg)

.jpg)