|

Shanghai Heng Sheng Industry Co., Ltd

|

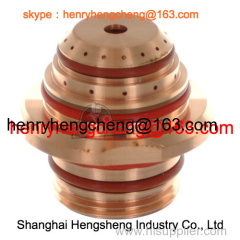

Hypertherm Plasma Cutting Nozzle / Cnc Plasma Cut Parts / Hypertherm Spare Parts / HSD130 Nozzle 220491

| Payment Terms: | T/T,WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hypertherm Plasma Cutter Machine Nozzle, Hypertherm HSD130 Nozzle 220525

Hypertherm Plasma Cutting Nozzle / Cnc Plasma Cut Parts / Hypertherm Spare Parts / HSD130 Nozzle 220530

Shanghai HengSheng Welding & Cutting Technology company are a professional manufacturer of plasma cutter consumables, Hypertherm plasma Cutting machine HSD130 accessories, plasma consumables. Hypertherm plasma HSD130 plasma cutting accessories, Hypertherm HSD130 plasma torch parts. Hyperherm plasma cutter nozzle 220489, plasma cutting nozzle 220492, 45A nozzle 220525, 50A nozzle 220530, hyperherm electrode 220525, plasma cutter tips 220487, hyperherm HSD130 swirl ring 220529, 130A swirl ring 220488, HSD130 Shield 220532, 220536, 220491, plasma cutter water tube 220937. plasma retaining cap 220578,

Our company adopts modern management mode and devotes itself to new high performance design and production of welding & cutting equipments, with continuous technique advantages innovation .All our staff are striving to realize the aim of "Create Chinese Brand ,Build First-Class Enterprise ",with the spirit of "Being honest and pragmatic ,making pioneering efforts and seeking perfection with persistency."

Machine | HEC NO. | Ref NO. | Description |

HSD 130 | H03528 | 220528 | Electrode,(Air)45/(Oxygen)50Amp |

H02487 | 220487 | Electrode,(Air)130/(Oxygen)130Amp | |

H03415 | 220415 | Electrode,130Amp (N2,H35) | |

H73529 | 220529 | Swirl Ring,(Air)45/(Oxygen)50Amp | |

H72488 | 220488 | Swirl Ring,(Air)130/(Oxygen)130Amp | |

H13525 | 220525 | Nozzle,45Amp (Air) | |

H13530 | 220530 | Nozzle,50Amp (Oxygen) | |

H13492 | 220492 | Nozzle,130Amp (Air) | |

H13489 | 220489 | Nozzle,130Amp (Oxygen) | |

H13535 | 220535 | Nozzle,130Amp (N2,H35) | |

H33578 | 220578 | Retaining Cap 45/50/130Amp (Air,Oxygen) | |

H33534 | 220534 | Retaining Cap 45/130Amp (N2 and F5,H35) | |

H23532 | 220532 | Shield,(Air)45/(Oxygen)50Amp | |

H22536 | 220536 | Shield,130Amp (Air) | |

H22491 | 220491 | Shield,130Amp (Oxygen) | |

H03415 | 220415 | Electrode,130Amp (N2,H35) | |

H03535 | 220535 | Nozzle,130Amp (N2,H35) | |

H33534 | 220534 | Retaining Cap 45/130Amp (N2 and F5,H35) |

Technical Support:

Plasma cutting technology

Several steps to improve cutting quality

1, the use of high quality of consumption

No high-quality parts of the high quality of cutting, parts must be made of high quality materials. Dimensions and tolerances are critical. If the machining is correct, the workpiece surface should be smooth without cracks and burr. The improvement of cutting quality usually starts with a new set of consumable parts.

2, select the appropriate consumption

Most plasma cutting machines adopt different consumable parts according to the cutting current and the use of gas. Check your operation manual to make sure you use The right consumption. Which the choice of the nozzle on the cutting quality of the greatest impact. In order to improve the cutting speed you want to allow the torch Perhaps the largest nozzle and the highest current; you may want to use the smallest nozzle and the lowest current to get the best cutting quality. Narrow slot cutting surface quality.

3, select the appropriate plasma gas

If the system can use a variety of or two kinds of plasma gas, according to the material and cutting thickness of the use of a most suitable gas. (see gas selection table) and confirm whether the gas pressure and flow are correct or not.

4, select the appropriate two gas

(see gas selection table) and confirm whether the pressure and flow of gas / water are correct.

5 cutting torch and workpiece perpendicular to

If the cutting torch and the material is not vertical, will cut out the angled slot. From the two aspects to check if the torch and workpiece angle of 90 degrees.

6 confirm the cutting direction

The good side is always on the cutting surface along the direction of walking on the right side of the torch (assuming the use of vortex ring is right)

7 setting the initial arcing distance

In the mechanical cutting system based on the arc starting distance guide line (see Rev. Arc adjustment range table) manually adjust the initial starting arc distance. The locking voltage regulator is highly regulated until the test cut and other parameters are determined.

8, adjust cutting speed

Select the initial cutting speed according to the cutting diagram in the operation manual. First cut and observe the angle of the plasma arc cutting workpiece. And then adjust the cutting speed to get the correct cutting arc angle.

.jpg)

.jpg)