|

Shanghai Heng Sheng Industry Co., Ltd

|

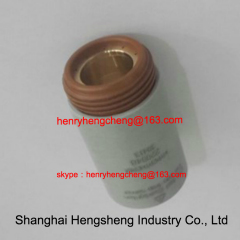

Powermax1250 Hypertherm Plasma Cutter Parts Shield Cap 120930 / 120929

| Payment Terms: | WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

We can offer you all plasma consumables for hyptertherm, Kjellberg, Esab, Koike, Komatsu, Thermadyne, such as: electrode, nozzle, shield, swirl ring,

Hypertherm Powermax1650 Shield Cap 220047 Plasma Cutter Consumables

We can offer you all plasma consumables for hyptertherm, Kjellberg, Esab, Koike, Komatsu, Thermadyne, such as: electrode, nozzle, shield, swirl ring, inner cap, retaining cap, water tube, torch body and so on.

We are specialized in the production of plasma cutting machine torch consumables manufacturer, we are engaged in the industry for 9 years.

Machine | HEC NO. | Ref NO. | Description |

PowerMAX45 PowerMAX1250 PowerMAX 1650 | H71925 | 120925 | Swirl Ring 40/60/80Amp |

H71051 | 220051 | Swirl Ring 100Amp | |

H01926 | 120926 | Electrode 40/60/80Amp | |

H01037 | 220037 | Electrode 100Amp | |

H11932 | 120932 | Nozzle 40Amp | |

H11931 | 120931 | Nozzle 60Amp | |

H11927 | 120927 | Nozzle 80Amp | |

H11011 | 220011 | Nozzle 100Amp | |

H11006 | 220006 | Nozzle 40Amp Without Cap | |

H11007 | 220007 | Nozzle 60Amp Without Cap | |

H11980 | 120980 | Nozzle 80Amp Without Cap | |

H11064 | 220064 | Nozzle 100Amp Without Cap | |

H11329 | 220329 | Nozzle 40Amp Fine Cut | |

H41928 | 120928 | Retaining Cap 40/60/80Amp | |

H41048 | 220048 | Retaining Cap 100Amp | |

H41061 | 220061 | Retaining Cap 40/60/80Amp | |

H41206 | 220206 | Retaining Cap 100Amp | |

H21930 | 120930 | Shield 40/60/80Amp | |

H21047 | 220047 | Shield 100Amp | |

H21979 | 120979 | Shieldg 40/60/80/100Amp | |

H21325 | 220325 | Shieldg 40Amp Fine Cut | |

H31404 | 220404 | Shieldg 40Amp Fine Cut | |

H81767 | 128767 | T100Torch Body | |

H82768 | 128768 | T100 Torch Head | |

H91755 | 128755 | T100 Torch Lead | |

H91752 | 128752 | T100 Torch Lead | |

H81754 | 128754 | Torch Main Body | |

H91643 | 128643 | Mounting Sleeve | |

H91710 | 128710 | Positioning Sleeve | |

H91753 | 128753 | Torch Lead | |

H91751 | 128751 | Torch Lead | |

H91759 | 128759 | Torch Lead | |

H91519 | 058519 | Torch O-ring |

Technical Support:

plasma cutting arc fault analysis

1. air pressure is too high

If the input air pressure is far more than 0. 45MPa, after the formation of the arc ion, the large flow of air will blow concentrated arc column, the energy of arc column dispersion, decreased the plasma arc cutting intensity. Cause the pressure is too high, the reasons are: improper input air conditioning, air filter regulator is too high or air filter valve failure. The solution is to check whether the pressure of the air compressor is adjusted properly, air compressor and air filter pressure relief valve is dysfunctional. After startup, such as rotating air filter relief pressure valve adjusting switch, gauge unchanged, indicating that the air filter relief pressure valve failure, need to be replaced.

2. cutting torch nozzle and electrode

Since the nozzle installation is improper, such as threads are not tightened, equipment of each block bit improper adjustment, need water cooling of the torch at work, not in accordance with the requirements of pass into the flow of cooling water and frequent arcs, will cause premature failure of the nozzle. Solution is, in accordance with the requirement of technology of the workpiece cutting and the correct adjustment of equipment gear, check the torch nozzle is installed firmly is, through the cooling water nozzle should be made in advance in cooling water circulation up. When cutting, cutting torch and workpiece thickness adjustment according to workpiece distance.

3. spark generator can not automatically cut off

Plasma cutting machine work, first of all to ignite the plasma arc, by the high frequency oscillator excited gas between the electrode and the inner wall of the nozzle, resulting in high-frequency discharge, the gas ionization and the formation of local small arc, the small arc by compressed air, ejected from the nozzle to ignite plasma arc. This is main task spark generator. Under normal circumstances, the working time of the spark generator is only 0. 5 ~ 1s, can not be automatically cut off the reasons for the general control circuit board components, the discharge electrode gap between the spark generator is not suitable. Solution: should always check the spark generator discharge electrode, so that the surface is smooth, timely adjustment of the discharge electrode gap of the spark generator (0. 8 ~ 1. 2mm), if necessary, replace the control panel.

4. other

In addition to the above reasons, the cutting speed is too slow, cutting the verticality of the torch and workpiece, and the operator of the plasma cutting machine familiarity, the operation level and influence the stability of the plasma arc, the user should notice in these aspects.

.jpg)

.jpg)