|

Shanghai Heng Sheng Industry Co., Ltd

|

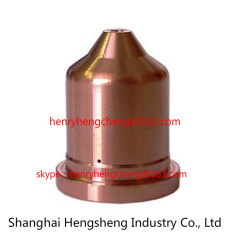

Hypertehr Nozzlde 220816 Plasma Consumables For

| Payment Terms: | T/T,WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

We can offer you all plasma consumables for hyptertherm, Kjellberg, Esab, Koike, Komatsu, Thermadyne, such as: electrode, nozzle, shield, swirl ring,

Hypertehr Nozzlde 220816 Plasma Consumables For Hypertherm PowerMax85

We can offer you all plasma consumables for hyptertherm, Kjellberg, Esab, Koike, Komatsu, Thermadyne, such as: electrode, nozzle, shield, swirl ring, inner cap, retaining cap, water tube, torch body and so on.

We are specialized in the production of plasma cutting machine torch consumables manufacturer, we are engaged in the industry for ten years.

Our products are processed using CNC machines, we have fifteen sets of high-precision testing equipment and Eighty experienced skilled workers.

In recent years, we have been sold in lots of countries and regions in Europe and Asia and gained good reputation widely with excellent quality . In order to meet customers' requirements and improve product quality, our company has already realized mechanical processing numerical control automatization production, and been committed to manufacturing products with best quality.

Machine | HEC NO. | Ref NO. | Description |

PowerMAX 45 PowerMAX 65 PowerMAX 85 PowerMAX 105

| H71857 | 220857 | Swirl Ring 45/65/85Amp |

H71994 | 220994 | Swirl Ring 45/65/85/105Amp | |

H71947 | 220947 | Swirl Ring FineCut | |

H01842 | 220842 | Electrode 45/65/85Amp | |

H11941 | 220941 | Nozzle 45Amp | |

H11819 | 220819 | Nozzle 65Amp | |

H11816 | 220816 | Nozzle 85Amp | |

H11930 | 220930 | Nozzle FineCut | |

H11797 | 220797 | Nozzle 65A/85A gouging | |

H11990 | 220990 | Nozzle 105Amp | |

H11991 | 220991 | Nozzle 105A gouging | |

H41854 | 220854 | Retaining Cap 45/65/85Amp | |

H41953 | 220953 | Retaining Cap 45/65/85A mechanized, ohmic | |

H41817 | 220817 | Shield 45/65/85Amp mechanized | |

H41818 | 220818 | Shield 45/65/85A drag-cutting | |

H41948 | 220948 | Shield FineCut, mechanized, ohmic | |

H41798 | 220798 | Shieldg 65/85A gouging | |

H41931 | 220931 | Deflector FineCut, handheld | |

H41993 | 220993 | Shield 105Amp mechanized | |

H41798 | 220798 | Shield 105A drag-cutting | |

H91955 | 220955 | Deflector 45/65/85A mechanized,unshielded |

Technical Support:

The problem of plasma cutting

5.1 no high frequency guidance arc

Check high frequency arc ignition circuit, first check the 110VAC, and observe the G1, G2 whether there is discharge sparks exist. If not, generally 110VAC did not come or fixed G1, G2 plastic board damp, damp after G2, G1 can not discharge and produce high pressure. Drying wood glue with a hair dryer to restore 110VAC. If there is still no guide arc, should check the high frequency arc, due to the high frequency of the skin effect, the high frequency line and the nozzle of the conductive ring is not good or because of the reasons for the sealing ring and the cooling water will not have a short circuit. Open the cutting gun, tighten the high frequency line or replace the sealing ring, generally can solve the problem.

5.2 there is no cutting arc

In the case of a high frequency spark observed, first check whether there is an open circuit voltage 400VDC. If not, check whether the phase of the three-phase power supply. High power silicon controlled rectifier and trigger circuit board in power supply box. If the power supply is normal, open the PLC control box, check the PLC input and output signals. The input consists of cooling water, cutting water flow signal, nitrogen and oxygen pressure signal. Cutting water flow signal without cooling water, cooling water pump should be replaced, without cutting the pump; nitrogen, oxygen pressure signal should be tested for nitrogen, oxygen source, and check whether the pipeline leaks. Such as the start conditions are met, will have to check the cutting gun, electrode rod sealing ring or the nozzle seal damage will water seeping into the cavity between the electrode and nozzle, leading to short-circuit DC power supply and the nozzle, can not form a loop with the workpiece. Replace the sealing ring, re assembled torch that can solve the problem.

.jpg)

.jpg)